Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

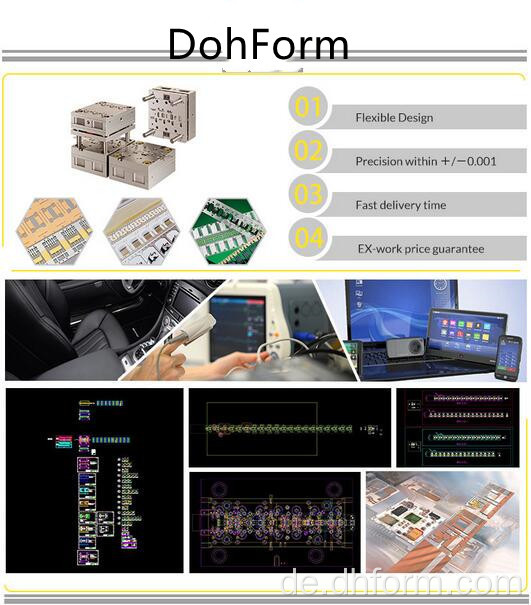

Marke: Dohform

Herkunftsort: China

Forming -Methode: Stanzform, Druckguss, Extrusionsform

Produktmaterial: Metall, Stahl, Aluminium, Eisen, Kupfer

Produkt: Fahrzeugform, Haushaltsgerät, Haushaltsprodukt

Verpakung: Standard exportierte Holzkiste verpackt, Begasungsvorgang (bei Bedarf)

Transport: Ocean,Land,Air

Ort Von Zukunft: Kunshan, China.

Unterstützung über: 30sets/month

Hafen: Shanghai,Ningbo,China

Zahlungsart: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Optimieren von Formenkosten und besten Gebrauch ist unsere Priorität.

Wir akzeptieren: 2D - DXF & DWG & PDF; 3D - UG-Dateien, wie STP, IGS, X_T., PRT.

Produktbeschreibung

Mold 2D + 3D-Zeichenentwurf:

|

Product name |

oem stainless steel sheet metal stamping mould |

|

Tooling steel material |

Depend on product, we help customer to choose the suitable material. Commonly used material as below: Carbide(CD650,V3,KD20), ASP-23, ASP-60, S55C---45#55, SKD11. |

|

Steel of mold base |

Depend on product, we help customer to choose the suitable material. Commonly use S45C. |

|

Mould Standard components |

HASCO, MISUMI, Meusburger, DME, etc. |

|

Die concept |

2-Plate Die, 3-Plate Die, Module Die |

|

Mold life |

Depends on the steel material and your requests. Commonly used: 50 Million to 300 Million Times |

|

Stamping Product |

PC Terminal, Power terminal, Press-Fit Terminal, Lead frame, SIM Spring, Connector Shield, Battery, Metal USB shell, custom stamping. |

|

Surface finish |

Depends on your requirements. Commonly: Texture Hatching, EDM Hatching, plating, Polishing, Diamoud Polishing, Mirror Polishing and so on. |

|

Delivery time |

Depends on the size and structure. Normally: 25-30 working days after 50% down payment. |

|

Terms of payment |

T/T, L/C, Western Union, D/A, D/P, Paypal. |

|

Machine center |

High speed CNC, Wire cutting, EDM, Grinder, Great Grinder, CNC milling, Drilling and milling, Stamping punching machines, injection machine, Inspection. |

|

R&D |

1. Drawing design and making for products and mold; 2. Mold drawing revising; 3. Production time and quality control in each machining process. (Our own EPR system). |

|

Production |

Pilot Run production and molding production can be provided. |

Produktionslauf

Wie kann man eine Form anpassen?

A) vor dem Verkaufsdienst

B) Produktionszeitraum

C) Nach dem Verkaufsdienst

Unsere Stempelprodukte

Produktgruppe : Progressive Stamping Die > Blechstempelteile

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.